CO2 Liquefaction Plant

CO2 Liquefaction plant is designed for the liquefaction and purification of Carbon dioxide gas to obtain food-grade CO2 recovery from the impure, low-pressure CO2 gas from the ammonia plant by-product gas and produce purified high-pressure liquid Carbon dioxide. The liquefaction of Carbon dioxide is a complex process that uses various compressions and expansions to produce high pressures and very low temperatures Liquid Carbon dioxide. The process of refrigerating a Liquid Carbon dioxide to a temperature below its critical temperature so that Liquid Carbon dioxide can be formed at some suitable pressure, also below the crucial pressure.

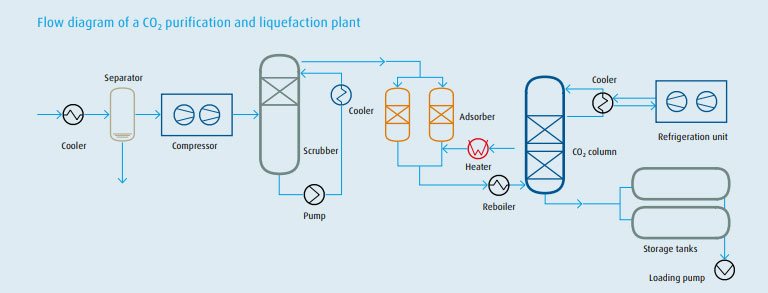

CO2 Purification & Liquefaction Process

Components of a CO2 Liquefaction Plant

Compression Systems:

At the core of this transformative process are high-performance compressors and pumps. These workhorse units play a pivotal role in elevating the pressure of gaseous CO2, priming it for the journey towards liquefaction. Side by side, cooling systems step in to chill the compressed gas, setting the stage for the next crucial phase.

Liquefaction Units:

Within the realm of liquefaction units, heat exchange technology takes center stage. This cutting-edge method harnesses the power of temperature differentials, efficiently transferring heat to or from the CO2 as it undergoes transformation. The orchestrated ballet continues with expansion valves, regulating the release of pressure and inducing a controlled expansion of the gas, ultimately yielding the coveted liquid CO2.

In the control room, the heartbeat synchronizes through a Human-Machine Interface, HMI Control Panel. This critical interface empowers operators to monitor, control, and optimize the entire process with precision. As the orchestra of components harmonizes under the HMI’s watchful eye, the CO2 liquefaction plant operates seamlessly, a testament to the integration of advanced technologies in the pursuit of efficiency and sustainability.