Distillery Based CO2 Recovery Plant

MOS Techno Engineers are reputed Distillery Based CO2 Recovery Plant manufacturers, Suppliers, and Exporters in India. We offer our clients a CO2 Recovery Plant from distillery & brewery designed with many years of experience and continuous development, based on comprehensive know-how relating to CO2 Recovery systems, Carbon dioxide gas production, Treatment Purification technology, and refrigeration engineering. We offer our clients the best solutions, which is a great benefit for the brewery & other industries due to their low investment and operating costs.

With a MOS plant for CO2 recovery plant from sources with a purity of above 90%, you get an advanced, sustainable, economical and future-oriented all-in-one concept. When required, preliminary purification grades and finishing processes, such as liquefying and compression of CO2 are fully integrated. We offer advanced recovery plant technology for the recovery of high-quality CO2 generated during combustion processes. The CO2 obtained fully complies with the specifications of the ISBT (International Society of Beverage Technologists).

CO2 Recovery Plant

CO2 Recovery Plant is wide in demand for soft drinks production industries, breweries, and many more related sectors for supplying fresh water and boiler feed water. Fabricated in accordance with industry standards, these CO2 Recovery Systems are available in different sizes to meet the client’s specific demands. These are essentially used for various industrial applications such as freezing units, gas dryers, and cylinder filling operations.

The constant process in this C02 gas recovery plant meets the international food grade quality standards. Our Advanced CO2 Recovery Plant to gain high-purity CO2 for all industrial and food applications, individually customized to our client’s specifications. Our Co2 recovery plant has Economical operating costs that are accomplished by employing innovative and proven technologies in the area of CO2 purification, CO2 liquefaction.

CO2 recovery plants have various applications. The fully automatic system correctly treat the CO2 generated during the fermentation process. The purified CO2 gas complies with all provisions for food-grade utilization and can be utilized for beverages & beer making. In addition to not requiring the procurement of carbon dioxide, this additional measure also results in cost savings, as the beer only comes into contact with carbon dioxide generated by the brewery itself.

CO2 Recovery Plants is monitored and controlled through an advanced HMI Control Panel, operators ensure optimal performance, seamlessly navigating the intricate processes of CO2 recovery with precision and environmental consciousness.

CO2 Recovery System

- Raw gas produced from the fermenters enters into the system in which the gas is fed in a foam trap for removal of foam

- The gas is pushed into the chain/series of scrubbing systems with the help of a booster blower. It comprises the pre-water scrubber, KMNO4 scrubber with dosing facilities

- In this, co2 recovery solution, CO2 gas is washed properly using water

- After this, the raw gas enters into a buffering vessel, from which, it moves towards two stages CO2 compressor for compression up to the desired pressure

- For removal of odor, the raw gas is fed into the dual tower activated carbon filter

- The raw gas is passed through the high-pressure precooler into the dual tower CO2 dryer

- It also passes through the liquefaction system and non-removal tower

- Finally, the liquid goes directly to the storage tank where the gas stored for a particular period of time

MOS CO2 recovery plant including indigenously advanced technology and continuous up-gradation of operational features. Appropriate focus on energy saving has previously commenced us to provide our clients with innovative solutions. We at MOS Techno Engineers consider continuous improvisation and technology up-gradation to obtain world-class products.

We conduct periodic quality inspections to advance the quality levels of our CO2 Recovery System. All our products are appropriately examined by our team of enthusiastic experts to ensure the quality and standards of each product delivered. Severe quality processes are adapted to meet all the safety standards of the CO2 Manufacturing Plant.

Utility requirement for different capacities Plant

| Plant Capacity | Power | Make Up Water | Liquid Co2 Storage Capacity |

Cooling Water | |||

| Kg/Hr. | KW | HP | M3/Hr. | Gal/Min | In Metric Ton | M3/Hr | Gal/Min |

| 100 | 33.5 | 44.9 | 0.4 | 1.76 | 15 | 7 | 30.8 |

| 250 | 83.7 | 112.3 | 1 | 4.4 | 25 | 17.5 | 77 |

| 500 | 167.5 | 22.1 6 | 2 | 8.8 | 50 | 30 | 132.1 |

| 750 | 251.2 | 336.9 | 5.9 | 13.2 | 100 | 45 | 198.2 |

| 1000 | 334.9 | 449.2 | 7.9 | 17.6 | 110 | 60 | 264.2 |

| 1500 | 502.4 | 673.8 | 6 | 26.5 | 150 | 90 | 396.3 |

| 2000 | 669.9 | 898.4 | 8 | 35.3 | 200 | 120 | 538.4 |

| * Larger Capacities are available on request as per customer requirement. | |||||||

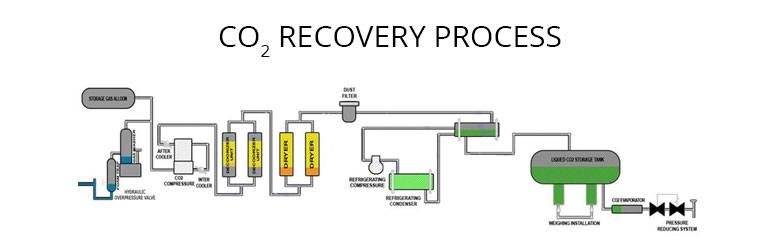

CO2 Recovery Process

CO2 Recovery plant intake carbon dioxide gas from the fermentation process and move through a series of purification processes. CO2 is separated from the deodorizer by a stainless steel CO2 foam trap.

Liquid CO2 Gas

Liquefied Carbon dioxide gas can be collected considerably at high pressure or Low pressure as below:

High-Pressure CO2 Gas

High-pressure liquid Carbon dioxide gas is produced by compressing the gaseous CO2 in multistage compressors in the operation of 69 bar (1000,76 psi) pressure, later cooling it to about 18 °C (64,4 °F). CO2 gas is then frequently supplied into specifically built stainless steel gas cylinders. Liquefied CO2 can be measured similarly to water, and this is the standard form of measuring it.

Low-Pressure CO2

Low-pressure liquefied CO2 is an alternative approach to collecting CO2 and is generated both by developing high-pressure CO2 to a lower pressure or by refrigeration. It is carried in specifically built CO2 storage tanks, gradually insulated and equipped with refrigeration units to hold the inner tank pressure at or below 21 bar (304,58 psi) and -18 °C (-0.4 °F) temperature.

Pressure switches are applied to regulate the refrigeration units, safety mechanisms. Electrical warnings alert served to discharge the tank pressure and put an alarm in the case of refrigeration failure.

Low-pressure liquefied CO2 gas transported by insulated CO2 Transport Tank or trailers, the liquid is easily carried from mobile to latent container by elevating or gravitation feed. Carbon dioxide can’t remain in the open environment in the liquid state CO2 must be stored under pressure or refrigeration (or a combination of both) to persist in the liquid state.