Dry Ice Machine

Owing to the in-depth experience of this domain, we offer the most advanced Dry Ice Machine combined with certified superior technology. MOS Dry Ice Making Machine developed to transform low-pressure liquid carbon die oxide into the solid form of carbon dioxide (CO2) at a pressure of 17.5 kg/cm2 (g). The liquid CO2 is passed through an expansion valve into an empty cylindrical chamber under normal atmospheric pressure. Further, it flushes into CO2 gas. This transformation from liquid to gas causes the temperature to drop quickly to 46% of the gas freeze into dry ice snow. The rest of the 54% C02 gas is released into the atmosphere or used again by recovering through compression and liquefaction. The dry ice snow is collected in a chamber condensed into blocks of 100mm X 100mm X 60mm.

The density of the dry ice maintains between 1.4 to 1.6-ton/m3 that helps it last longer and easier to handle. This machine facilitates the fastest and cost-effective method of producing dry ice that does not dissolve as water and is notably cold. The dry ice making becomes an exceptional saving for the storage and transport of various food and medical vaccines.

Advantages of an in-house dry ice production:

- Cost-effective & timely availability. Minimized logistics cost compared with buying and disposing of dry ice.

- For dry ice blasting and effective cleaning results, because the fresher the dry ice, the more efficient the cleaning

- In-house dry ice production thus can reduce dry ice usage by 30-50%.

- Reduction of dry ice lost due to sublimation.

The MOS100 machine having a production capacity of 100 kg per hour, is becoming to make extensive volumes of dry ice for cooling purposes. These dry ice machines are commanded by a sturdy hydraulic unit highlighting a push-button for an immediate production process.

PLC Control System

The snowing chamber operation continues with an electrically operated solenoid valve. The hydraulic cylinders are operated with the help of the PLC. The automatic production system will work with PLC and pressure switches. The machine is auto programmed and shall provide all analytics for the number of bricks manufactured in one run. All operations are controlled by a PLC Unit and are fully automated control of oil temperature and dry ice covering the manner ensures constant dry ice production without any manual supervision.

We are getting demand for Dry Ice Making solutions from various pharmaceuticals, hospitals, food, and logistic transport industries. We offer an extensive assortment of dry ice machines and pelletizers that can produce blocks of various dimensions. Dry ice is the crystallized form of carbon dioxide CO2. In comparison to the ice obtained from water, that survives at 32°F (0°C) of temperatures and below, dry ice is extremely cold, -109°F (-79°C) and remain in a cold state for a longer time.

Technical Specifications

- Material of construction: SS-304

- Size: 100mm X 100mm X 60mm

- Method of expansions: Solenoid valve-controlled with expansion nozzle.

Hydraulic System

- Hydraulic pump: High pressure and high volume hydraulic pump of reputed manufacturer

- Controls: Auto controlled valves for movement of cylinders. All components are from reputed manufacturers etc.

- Electrical motor: 5 hp/1440 rpm motor. The motor and the base frame is mounted on a common skid to save space.

- Hydraulic tank: CS. Capacity 180 litres. With necessary accessories such oil level indicator, breather, support frame etc.

- Hydraulic cylinders: High performance hydraulic cylinders with SS rod, all components are designed for no oil leak and long life.

Base Frame

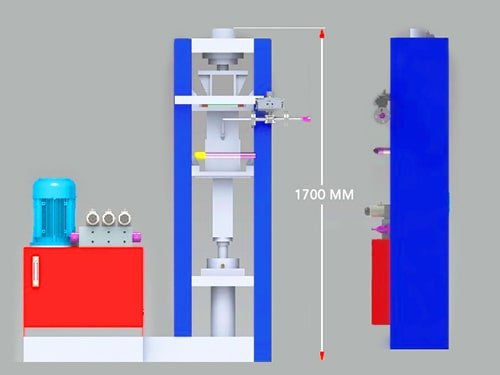

- Size: Approx 1700mm (H) x 1250 mm (L) x 600 (W):

- Room Space Required: 3.6 mt (L) X 3.6 mt (W) X 3.0 mt (W)

Note: Room should be well ventilated.

Control System

The snowing chamber operation is with an electrically operated solenoid valve. The hydraulic cylinders are operated with the help of the PLC. Automatic operation the system will work with PLC and pressure switches. Block size shall be 100mm X 100mm X 60mm. The machine is auto programmed and shall provide all analytics for the number of bricks manufactured in one run.