Air separation Plant

MOS Techno Engineers counted as the pioneers among the Air Separation Plants Manufacturers. Air Separation Unit designed by our engineers is the most efficient and cost-effective technology for the industries of medium to large scale. We have ASU’s plant that has comprehended for its reliability and performance. Our numerous clients typically adopted our plants to produce various high purity gases like oxygen, nitrogen, and high purity gases in their liquid form. Air Separation Plant cost offered by MOS Techno Engineers is a much-competing price in the industry.

Air Separation Unit

We build and export our own air separation system and we propose the best cryogenic air separation plant capital cost. Our Air Separation plants producing liquefied industrial gas produce fitting cryogenic technology. With the technologically seasoned team of engineers, we have earned the name among the top air separation plant manufacturers in India.

Our ASU plant consists of the following equipment

- Plate type heat exchanger

- Medium pressure column

- Low-pressure column

- Expansion turbine

- Air liquefier

- Rich liquid sub-cooler

- Sub-cooler

- Liquid Nitrogen separator

- Liquid Oxygen separator

Our technologically advanced plants can generate up to 99.7% high purity oxygen gas and up to 99.99% high purity nitrogen gas. Automated air separation plants are in very demand with assorted capabilities that vary from 50 m3/hr up to 5000 m3/hr.

Cryogenic Air Separation Process

The cryogenic air separation plant production process is the most successful air separation process, practiced constantly in medium to large scale gas production plants. It is the most adopted technology for the generation of nitrogen (N2), oxygen (O2), and argon (AR) as gases and/ or liquid gases and thought to be the most cost-effective technology for high production rate plants.

Air Separation Unit Specification

| Oxygen Production | Nitrogen Production | ||||||

| Alternative | Gas Quantity | Gas Purity | Product Pr. | Gas Quantity | Gas Purity | Product Pr. | |

| 1 | MOS 40 | 40 cu.m/hr | 0.995 | 150 kg/cm2 | * 210 cu.m/hr | 0.96 | 0.1 kg/cm2 |

| 2 | MOS 80 | 80 cu.m/hr | 0.995 | 150 kg/cm2 | * 400 cu.m/hr | 0.96 | 0.1 kg/cm2 |

| 2A | MOS 80 | 70 cu.m/hr | 0.996 | 150 kg/cm2 | * 80 cu.m/hr | 0.995 | 0.1 kg/cm2 |

| 2 | MOS 100 | 100 cu.m/hr | 0.995 | 150 kg/cm2 | * 500 cu.m/hr | 0.96 | 0.1 kg/cm2 |

| 3A | MOS 100 | 90 cu.m/hr | 0.996 | 150 kg/cm2 | * 100 cu.m/hr | 0.995 | 0.1 kg/cm2 |

| 4 | MOS 150 | 150 cu.m/hr | 0.995 | 150 kg/cm2 | * 700 cu.m/hr | 0.96 | 0.1 kg/cm2 |

| 4A | MOS 150 | 135 cu.m/hr | 0.996 | 150 kg/cm2 | * 150 cu.m/hr | 0.995 | 0.1 kg/cm2 |

| Oxygen Production | Nitrogen Production | ||||||

| Alternative | Gas Quantity | Gas Purity | Product Pr. | Gas Quantity | Gas Purity | Product Pr. | |

| 1 | MOS 200 | 200 cu.m/hr | 0.995 | 150 kg/cm2 | * 700 cu.m/hr | 0.98 | 0.1 kg/cm2 |

| 1A | MOS 200 | 180 cu.m/hr | 0.996 | 150 kg/cm2 | * 400 cu.m/hr | 0.9999 | 0.1 kg/cm2 |

| 2 | MOS 300 | 300 cu.m/hr | 0.995 | 150 kg/cm2 | * 1300 cu.m/hr | 0.98 | 0.1 kg/cm2 |

| 2A | MOS 300 | 270 cu.m/hr | 0.996 | 150 kg/cm2 | * 700 cu.m/hr | 0.9999 | 0.1 kg/cm2 |

| 2 | MOS 400 | 400 cu.m/hr | 0.995 | 150 kg/cm2 | * 1600 cu.m/hr | 0.98 | 0.1 kg/cm2 |

| 3A | MOS 400 | 360 cu.m/hr | 0.996 | 150 kg/cm2 | * 900 cu.m/hr | 0.9999 | 0.1 kg/cm2 |

| 4 | MOS 600 | 600 cu.m/hr | 0.995 | 150 kg/cm2 | * 2940 cu.m/hr | 0.98 | 0.1 kg/cm2 |

| 4A | MOS 600 | 540 cu.m/hr | 0.996 | 150 kg/cm2 | * 1400 cu.m/hr | 0.9999 | 0.1 kg/cm2 |

| 5 | MOS 1000 | 1000 cu.m/hr | 0.995 | 40 kg/cm2 | * 4500 cu.m/hr | 0.98 | 0.1 kg/cm2 |

| 5A | MOS 1000 | 900 cu.m/hr | 0.996 | 40 kg/cm2 | * 2000 cu.m/hr | 0.9999 | 0.1 kg/cm2 |

Air Separation Plant Design

- How many products are required (likely simply oxygen or nitrogen, both oxygen and nitrogen, or nitrogen, oxygen, and argon)

- Required purities level of the output.

- Gaseous product delivery pressures.

- Lastly, whether the products need to be stored in Liquid form.

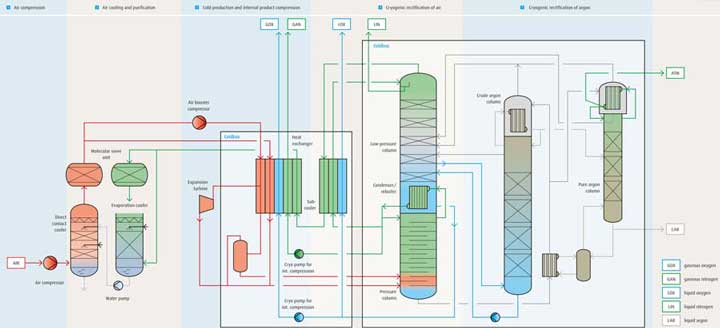

Air compression

- Compression of ambient air by a multi-stage turbo compressor with intercoolers at a supply pressure of approx. 6 bar.

- Removal of dust particles by a mechanical air filter at the inlet of the compressor.

Air cooling and purification

- Cooling of process air with water in a direct contact cooler and removal of water-soluble air impurities.

- Chilling of cooling water in an evaporation cooler against dry nitrogen waste gas from the rectification process.

- Removal of CO₂, water, and hydrocarbons from the process air is periodically loaded/regenerated molecular sieve adsorbers.

Cold production and internal product compression

- Cooling of process air in heat exchangers down to nearly liquefaction temperature by means of countercurrent with gas streams from the rectification process.

- Further compression of a sidestream of process air by an air booster compressor. Expansion and cold production of the boosted air stream in an expansion turbine.

- Expansion and liquefaction of a sidestream of the boosted air in a liquid separator.

- Evaporation and warming to the ambient temperature of the pumped oxygen and nitrogen product in high-pressure heat exchangers.

Cryogenic rectification of air

- Pre-separation of the cooled and liquefied air within the pressure column into oxygen-enriched liquid in the column sump and pure nitrogen gas at the column top.

- Liquefaction of the pure nitrogen gas in the condenser/reboiler against boiling oxygen in the sump of the low-pressure column. Liquefied nitrogen provides the reflux for the pressure column and (after sub-cooling) for the low-pressure column.

- Separation of the oxygen-enriched liquid within the low-pressure column into pure oxygen in the sump and nitrogen waste gas at the top.

Our ASU Plants are designed to produce the purest oxygen, and argon from the air through the process of concentration, cooling, liquefaction and distillation columns of air. Air is separated for production of oxygen, nitrogen, argon and ‐ in some special cases ‐ other rare gases (krypton, xenon, helium, neon) through cryogenic rectification of air. The results can be performed in gaseous form for pipeline supply or as the cryogenic liquid for storage and supplied by truck. The cryogenic air separation process is one of the most successful air separation processes, most often operated in medium to large scale industries.

Pure Oxygen Production

Cost-optimized process for small- and medium-sized oxygen production plants as in the conventional manufacturing process, a gas stream from the low-pressure column is feed into the plant. Due to the optimized packing, the gas stream is already free of nitrogen. Therefore, only the remaining oxygen is collected to be in the plant, and oxygen purity and recovery can be kept at the same level as in the conventional process. The additional pure Oxygen column is no longer required.