Oxygen Gas Plant

Oxygen gas plants are systems that produce high-purity oxygen (93±3%) and can handle pressures up to 100 bars. Many industries, such as hospitals, steel manufacturing, metal refining, chemicals, pharmaceuticals, glass, and ceramics, use them. These plants provide oxygen efficiently, making them essential for both industrial and medical purposes.

Oxygen is produced from air using methods such as pressure swing adsorption or membrane separation. These methods are used to separate oxygen from other substances. Oxygen Gas Plants utilize advanced Automation Control Panels to precisely regulate the production process, ensuring efficient oxygen generation. These panels monitor and adjust parameters, guaranteeing optimal performance and safety.

These large cryogenic Oxygen Plants are easy to operate, making them suitable for emergencies. It is a perfect option for industries that strive for high performance and efficiency. These large cryogenic plants are ideal as they require little effort and less maintenance.

Key Applications of Oxygen Gas Plants

Oxygen gas plants serve a range of industries with versatile applications, including:

- Hospitals – Provide critical oxygen supply for medical treatments, surgeries, and emergency respiratory support.

- Steel Manufacturing – Optimize combustion processes and enhance production efficiency.

- Metal Refining – Assist in smelting and refining operations to improve output quality.

- Chemical & Pharmaceutical Industries – Enable oxidation processes and synthesis of chemical compounds.

- Glass & Ceramic Production – Enhance manufacturing processes through oxygen-enriched combustion.

MOS Techno Engineers is a leading oxygen gas plant manufacturer. Our company has a lot of experience designing and building plants that produce pure Oxygen and Nitrogen. Not only does our plant produce high-quality oxygen gas, but it is also very efficient.

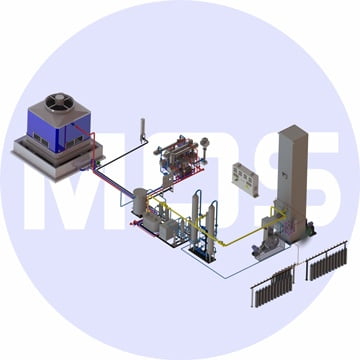

An air separation plant filters and compresses ambient air to isolate individual gases like Oxygen, Nitrogen, and argon. Our oxygen and nitrogen gas plants use top-tier engineering and cutting-edge cryogenic technology.

The MOS Oxygen Plant can produce pure Oxygen and Nitrogen gas. It comes with an internal compression Liquid Oxygen Filling Pump. That pump can fill up to 500 metric tons cylinder capacity per year. Yet, these machines take time to cool down the pace of the on-site servicing process.

Our team takes care of the client requirements in compliance with the standards. MOS Oxygen Plant saves a lot of production costs due to low power use.

Our high-performing and cost effective oxygen plant reduce pressure to 32-35 kg/cm2. It also can reduce energy consumption by 15%. Our oxygen plants are the most advanced, automated, and monitored. As a result, they offer a high degree of safety and reliability.

Our team of professionals has been designing and installing industrial gas plants for almost two decades. We build each oxygen generation plant to match a client’s needs while still meeting our high efficiency standards. These plants operate on a lower power consumption, saving you money on operating an oxygen plant project cost.

We provide industrial solutions, such as air separation and medical oxygen plant cost in India. Our oxygen plant uses advanced technology for manufacturing worldwide.

Oxygen Manufacturing Plant

Our Automation Control Panels ensure seamless operation in oxygen plant production processes. From precise monitoring to efficient control, our panels optimize performance, ensuring reliability and productivity.

As a trusted Oxygen Plant Manufacturer, we incorporate advanced features to separate moisture and CO2, making our oxygen plants cost-efficient and highly reliable. We use the latest technology to develop oxygen production plants for medical and other industries.

We made a special oxygen plant for hospitals to produce medical oxygen for individual customers. For example, oxygen plants for medical applications may only work for some industries.

Oxygen production plant cost

We have a wide range of oxygen plants for industrial and medical applications from oxygen production plants. The MOS Oxygen manufacturing plant can fill 10 to 500 cylinders per day. oxygen factory in India setup cost differs according to the area and production capacity. Clients can contact us to get an estimate for their requirements.

Features of MOS Oxygen Gas Plants

- Advanced Technology Integration

- Internal compression liquid oxygen filling pumps capable of filling up to 500 metric tons cylinder capacity annually.

- Cutting-edge cryogenic systems for pure oxygen and nitrogen production.

- Cost Efficiency

- Reduces energy consumption by up to 15%.

- Lowers operational pressure to 32-35 kg/cm², cutting production costs significantly.

- Unmatched Reliability and Safety

- Fully automated and monitored systems ensure high performance and maximum safety standards.

- Tailored Solutions

- Customized plant designs to meet specific client needs, ensuring seamless compatibility with industry demands.

Oxygen Gas Generator

All our oxygen generators use modern and superior cutting-edge technology. It can produce 99% pure O2 using the pressure swing adsorption technique.

Technical Specification

Plant capacity: The plant is versatile and can be set for a cycle to produce any following alternatives.

| Oxygen Production | Nitrogen Production | ||||||

| Alternative | Gas Quantity | Gas Purity | Product Pr. | Gas Quantity | Gas Purity | Product Pr. | |

| 1 | MOS 40 | 40 cu.m/hr | 0.995 | 150 kg/cm2 | * 210 cu.m/hr | 0.96 | 0.1 kg/cm2 |

| 2 | MOS 80 | 80 cu.m/hr | 0.995 | 150 kg/cm2 | * 400 cu.m/hr | 0.96 | 0.1 kg/cm2 |

| 2A | MOS 80 | 70 cu.m/hr | 0.996 | 150 kg/cm2 | * 80 cu.m/hr | 0.995 | 0.1 kg/cm2 |

| 2 | MOS 100 | 100 cu.m/hr | 0.995 | 150 kg/cm2 | * 500 cu.m/hr | 0.96 | 0.1 kg/cm2 |

| 3A | MOS 100 | 90 cu.m/hr | 0.996 | 150 kg/cm2 | * 100 cu.m/hr | 0.995 | 0.1 kg/cm2 |

| 4 | MOS 150 | 150 cu.m/hr | 0.995 | 150 kg/cm2 | * 700 cu.m/hr | 0.96 | 0.1 kg/cm2 |

| 4A | MOS 150 | 135 cu.m/hr | 0.996 | 150 kg/cm2 | * 150 cu.m/hr | 0.995 | 0.1 kg/cm2 |

Note: Above 50,100,200 and 300 cu.m/hr of Nitrogen will be used for regeneration of driers respectively for 40,80,100 and 150 cu.m/hr Plants.

| Oxygen Production | Nitrogen Production | ||||||

| Alternative | Gas Quantity | Gas Purity | Product Pr. | Gas Quantity | Gas Purity | Product Pr. | |

| 1 | MOS 200 | 200 cu.m/hr | 0.995 | 150 kg/cm2 | * 700 cu.m/hr | 0.98 | 0.1 kg/cm2 |

| 1A | MOS 200 | 180 cu.m/hr | 0.996 | 150 kg/cm2 | * 400 cu.m/hr | 0.9999 | 0.1 kg/cm2 |

| 2 | MOS 300 | 300 cu.m/hr | 0.995 | 150 kg/cm2 | * 1300 cu.m/hr | 0.98 | 0.1 kg/cm2 |

| 2A | MOS 300 | 270 cu.m/hr | 0.996 | 150 kg/cm2 | * 700 cu.m/hr | 0.9999 | 0.1 kg/cm2 |

| 2 | MOS 400 | 400 cu.m/hr | 0.995 | 150 kg/cm2 | * 1600 cu.m/hr | 0.98 | 0.1 kg/cm2 |

| 3A | MOS 400 | 360 cu.m/hr | 0.996 | 150 kg/cm2 | * 900 cu.m/hr | 0.9999 | 0.1 kg/cm2 |

| 4 | MOS 600 | 600 cu.m/hr | 0.995 | 150 kg/cm2 | * 2940 cu.m/hr | 0.98 | 0.1 kg/cm2 |

| 4A | MOS 600 | 540 cu.m/hr | 0.996 | 150 kg/cm2 | * 1400 cu.m/hr | 0.9999 | 0.1 kg/cm2 |

| 5 | MOS 1000 | 1000 cu.m/hr | 0.995 | 40 kg/cm2 | * 4500 cu.m/hr | 0.98 | 0.1 kg/cm2 |

| 5A | MOS 1000 | 900 cu.m/hr | 0.996 | 40 kg/cm2 | * 2000 cu.m/hr | 0.9999 | 0.1 kg/cm2 |

Note: Above 200, 300, 400, 600 and 1000 cu.m/hr of Nitrogen will be used for regeneration of driers respectively for 200, 300, 400, 600 and 1000 cu.m/hr Plants.

The above plant capacities are based on ambient conditions of 27o deg temperature 760 mm of Hg pressure and 70% relative humidity and 300 ppm (0.03%) of Carbon Dioxide is allowed as an impurity.

Plant Specification

| Minimum Order Quantity | 1 Set |

| Automatic Grade | Automatic |

| Design | Standard |

| Capacity | 50- 1000 m3/hr |

| Purity Oxygen | 93+- 3% |

| Purity Nitrogen | 93+- 3% |

| Applications | Medical & Industrial |

| Certification | ISO 9001:2008 |

| Life | Long Life |

| Usage | Oxygen Production |

Medical oxygen gas plant

MOS Techno Engineers provided Medical Oxygen Plant, a dependable source for continuous medical grade oxygen generation. We are the top oxygen plant manufacturer in India, providing oxygen manufacturing plants for various industries across the globe.

Our PSA Oxygen generators have verified themselves as the primary source of Oxygen in hospitals. They require less maintenance than other systems and provide continuous oxygen delivery at a lower cost. All of our PSA Oxygen Plants function more quietly and efficiently.

Cryogenic Oxygen Plant

Cryogenic technology is extensively practiced by oxygen plant suppliers worldwide. We always use advanced technology to fabricate and manufacture cryogenic air separation plant. The client knows our oxygen plants for their reliable and durable production capabilities.

The design of our oxygen plant operates with top quality elements. Advanced cryogenic technology builds it efficient and safe to use in hospitals. Our company offers a wide range of oxygen gas plants to the market.

We use pressure swing adsorption technology to ensure a continuous supply of clean Oxygen. We offer a wide range of oxygen plants for applications in various industries.

Air separation plant produces individual or combined industrial gasses (Nitrogen and Oxygen). These are the two gases that industries use the most. Our advanced oxygen production plant generates up to 99% pure oxygen. We deliver oxygen manufacturing plants in various capabilities starting from 50 m3/hr.

This size fits the needs of all industry types. It is a perfect option for industries that search for clean and zero-waste practices. Please get in touch with us for more information on the cost of installing an oxygen gas plant in India.

Working Process of MOS Oxygen Plant

Air is compressed, and Oxygen is separated from other gases using zeolite molecular sieves. This process involves two towers filled with zeolite molecular sieves, which adsorb Nitrogen and discharge waste. The Oxygen generated is 85-94% pure. When Nitrogen saturates one tower, the process changes to the other, providing continuous oxygen generation.

An air compressor takes in air from the atmosphere and reduces its pressure. It goes through coolers and water separators after each stage. The air is dried and purified using a molecular sieve battery. It is cooled by excess nitrogen and oxygen in an exchanger.

Expansion Engine for Air Separation

An expansion engine and heat exchange system cool the warm air entering it. The cold side splits off into two streams: one is cooled by an additional refrigeration unit. Another column of air passes into a lower pressure column, where the air streams unite and partially liquefy.

The liquid air then passes through an expansion valve to the upper column at a lower pressure than its counterpart. Similarly, Nitrogen moves from a low level. Gases rise into heat exchangers, where the condenser cools them. The cooled gases are released and flow past both sides of the heat exchanger to the ground.

Before air separation, it passes through the pressure column. Oxygen and Nitrogen gas are turned into a liquid form in the condenser/reboiler against boiling Oxygen. Liquefied Oxygen provides the reflux for the pressure column and (after sub-cooling) for the low-pressure column.