Stack Gas CO2 Recovery Plant

MOS Techno Engineers offers CO2 Stack Gas Recovery Plant from distillery & brewery are the result of many years of experience and continuous development, based on comprehensive know-how relating to CO2 Gas production treatment Purification technology and refrigeration engineering. We build & offer our customers the best solutions, which is a great benefit for the brewery & other industries due to their low investment and operating costs.

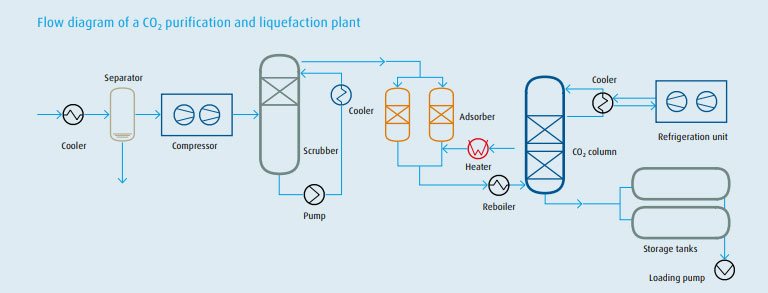

MOS Techno Engineers innovative CO2 stack gas recovery technology turns your vent flue gas into a usable and profitable source of CO2.CO2 gas won by a CO2 Stack Gas Recovery System is a by-product of flue gas production from boilers as well as from other flue gas sources offering an economic CO2source to any CO2 consumer or reseller. The flue gas initially treated for removal of Sulphur compounds before it is transported into the absorber where the CO2 gas is extracted by absorption utilizing with our specially formulated solvent. This solvent is then thermally treated by the steam-controlled re-boiler in order to separate the CO2 gas from the absorption solution. After the subsequent compression, purification and liquefaction the CO2 quality meets the specifications of ISBT.

CO2 Recovery Process

- Raw gas produced from the fermenters enters into the system in which the gas is fed in foam trap for removal of foam

- The gas is pushed into the chain/series of scrubbing systems with the help of booster blower. It comprises of the pre-water scrubber, KMNO4 scrubber with dosing facilities

- In this, the CO2 gas is washed properly using water

- After this, the raw gas enters into a buffering vessel, from which, it moves towards two stages CO2 compressor for compression up to the desired pressure

- For removal of odor, the raw gas is fed into the dual tower activated carbon filter

- The raw gas is passed through the high-pressure precooler into the dual tower CO2 dryer

- It also passes through the liquefaction system and non-removal tower

- Finally, the liquid goes directly to the storage tank where the gas stores for a particular period of time

CO2 Recovery Plant Specifications

| Utility requirement for different capacities Co2 Recovery Plant | |||||||

| Plant Capacity | Power | Make Up Water | Liquid Co2 Storage Capacity |

Cooling Water | |||

| Kg/Hr. | KW | HP | M3/Hr. | Gal/Min | In Metric Ton | M3/Hr | Gal/Min |

| 100 | 33.5 | 44.9 | 0.4 | 1.76 | 15 | 7 | 30.8 |

| 250 | 83.7 | 112.3 | 1 | 4.4 | 25 | 17.5 | 77 |

| 500 | 167.5 | 22.1 6 | 2 | 8.8 | 50 | 30 | 132.1 |

| 750 | 251.2 | 336.9 | 5.9 | 13.2 | 100 | 45 | 198.2 |

| 1000 | 334.9 | 449.2 | 7.9 | 17.6 | 110 | 60 | 264.2 |

| 1500 | 502.4 | 673.8 | 6 | 26.5 | 150 | 90 | 396.3 |

| 2000 | 669.9 | 898.4 | 8 | 35.3 | 200 | 120 | 538.4 |

| * Larger Capacities are available on request as per customer requirement. | |||||||